PROFORGED

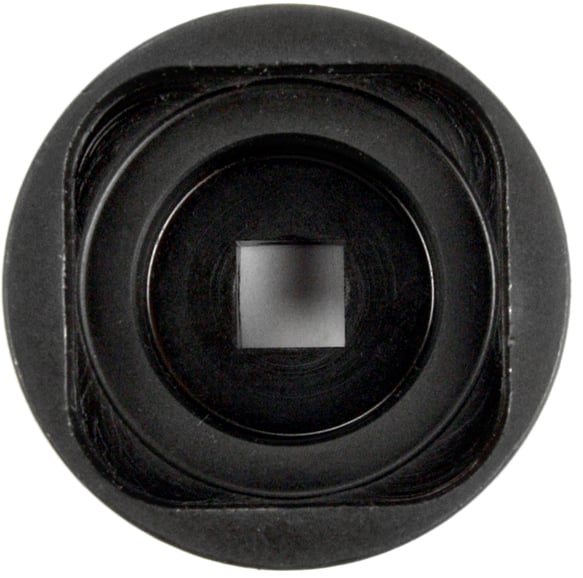

PROFORGED UPPER BALL JOINT REMOVAL TOOL

1/2″ Drive Socket for Most Screw-in Style Ball Joints on 1957-1989 Chrysler / Dodge / Plymouth.

Part # 124-10001

REMOVE MOPAR BALL JOINTS WITH EASE. Our ultra-strong removal tool accepts a 1/2 inch drive ratchet and makes removing the upper ball joint a breeze. This fits any K772-style ball joint.;1,000,000 MILE WARRANTY. You can use our ball joint tool with confidence knowing that every part we sell is backed by our industry-leading 1,000,000 mile limited warranty. We can offer this because our parts are engineered, tested, re-tested, and subject to strict quality control procedures – our quality is second to none.;BUILT FOR PROFESSIONALS. There’s a reason why the most well-respected performance suspension brands use Proforged products – we’re fanatical about quality, performance, and durability. Professionals save time and money with our competitively-priced products that outlast inferior brands. Do the job with confidence – replace your worn components with the leader in performance center links: Proforged.;BUY WITH CONFIDENCE. There’s a reason that the most well-respected performance suspension manufacturers buy from Proforged: we’re the only brand of chassis parts that offers race-day performance at a price within your budget – and backs it up with a 1,000,000 mile limited warranty. Buy today and get your car, truck, or racecar back on the road and stronger than ever.

Features:

- 1/2″ Drive Socket

- Fits Most 1957-1989 Mopar Screw-In Style Ball Joints

| Brand | Proforged |

|---|---|

| Emission Code | 6 |

| Product Type | Ball Joint Tool |

| UPC | 849180000086 |

| Part Number | 124-10001 |

Reviews

There are no reviews yet.